|

WEAR GENERATES WEAR |

||

1 Micron Depth Filtration Systems: Clean Your Oil, Protect Your Machine, SAVE THE OIL, SAVE THE ENVIRONMENT

|

FILTRATION OF FRYING/COOKING OIL |

|

Make your frying healthier and extend the life of oil |

| STRAINING IS NOT ENOUGH; YOU NEED FILTERING | ||||||||

|

|

||||||||

|

Many applications in frying oil cleaning relies on use of strainers; but this is not adequate to remove fine food particles.

|

||||||||

|

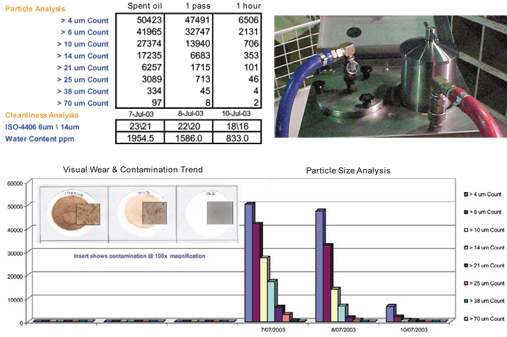

AFTER STRAINING, VERY FINE PARTICLES THAT CAN NOT BE SEEN BY BARE EYE REMAIN IN OIL As can be seen in the report below, particles under 25 micron can not be filtered and remain in the oil. According to ISO4406 standard, particles ara analysed within certain size ranges, 4-6-14-21-25 microns. These fine food particles will burn to accelerate oxidity and make the oil look darker/hazier. |

||||||||

|

|

|||||||

| Top: Cooking oil on the left and filtration results after one and multiple passes. | ||||||||

| Left: Particle sizes for the above oil samples after analysis | ||||||||

| Two international standards are used to measure contamination: ISO4406 and NAS1638 (later AS4059). | ||||||||

|

NAS1638 is used in general for components. Particles in a 100 mL of sample are count in 5 different size ranges (5-15, 15-25, 25-50, 50-100, >100 microns) and designated with a code (from00 to 12) according the particle count for each size. The highest, i.e. the worst code is taken to report as the contamination level for that sample. See About Oil >>>> |

||||||||

| FILTRATION IS NECESSARY TO PROTECT OIL QUALITY AND TO EXTEND OIL LIFE |

|

| The fine particles that can not be held by the coars strainers will burn and deteriorate the oil quality and accelerate acidity. These fine particles also stick on the fryings, spoil the taste and look, and cause risk of cancer. The picture and video shows how the oil becomes clear and lighter after filtration. |

| A filtration unit to filter cooking/frying oil at 200 0C. Filter body is stainless steel. Sealings and O-rings are viton.Oil is passed through 3 level of strainers, 50-25-10 microns before passed from 2 micron fine filter. Strainers are easily removed and cleaned | ||||

|

||||

| RECONDITIONING/REGENERATION OF FRIED OIL | |

|

Suggested frying temperature for frying oils is 180 0C dir. Frying at higher temperatures will cause oil smokes and generation of trans fats in oil. Acid number in oil will increase which make the oil unusable after vertain level. The oil is passed through regeneration/reconditioning unit which will reduce oxidation products and make the oil look lighte and reduce bad odeur. Clay is not a chemical and used in oil production to change the color of new oil. ATTENTION: No chemicals is used to make the color lighter. Chemicals do not reduce acid or unhealthy by-products while changing the color to lighter. Acidity level is the same. |

|

|

FILTRATION PRODUCTS Filtration can be done during frying while the oil is at process temperature. For regenration after processing, temperature may be about 100 0C for the clay to absorb oxidation by-products. |

||||

|

|

|

|

|

|

|

|

|

|

|

|

Filtration units at various capacities: Depending on the paticles formations in oil, various sizes of strainers may be added to support fine filters. This will increase the filtering life of the fine filters, the strainer elements can be reused after cleaning/washing. |

10 L/min hot oil filtration and regeneration machine. Unit on the left hand side is regeneration unit. |

0 L/min hot oil filtration and regeneration machine. | ||

| PRODUCT | CAPACITY | OPERATING TEMPERATURE | STRAINERS | SUCTION STRAINER | ELECTRIC POWER |

|

PUCO-MF1 |

10 L/Min |

80 0C or 200 0C Stainless steel pump is necessary for high temperature filtration. |

Can be installed with the fine filter in the same housing; also can be a separate unit depending on the particles concentration in oil: 100-50-25-10 microns |

May be necessary to use before the pump. Size depends on the particle size and concentration. |

220 / 380 VAC; motors are with thermal protection |

|

PUCO-MF2 |

20 L/Min |

||||

|

PUCO-MF4 |

40 L/Min |

||||

|

PUCO-2MF4 |

80 L/Min |

|