|

WEAR GENERATES WEAR |

||

Clean your oil with our ultra-fine filtration systems, protect your machine

|

|

TURBINE AND TRANSFORMER OIL FILTRATION |

|

MAINTAIN 'BETTER THAN TARGET' OIL CLEANLINESS |

![]() Transformer Oil

Filtration

Transformer Oil

Filtration ![]() Turbine and Wind Generator Oil Filtration

Turbine and Wind Generator Oil Filtration

| TRANSFORMER OIL |

TURBINE OIL |

|

| 1. |

Transformer Oil Filtration Units (with water absorbant element and heater options) |

3- Filtration Units |

| 2. |

Regeneration Units (optional addition to filtration unit) |

4- Water Absorbing Units |

| 3. |

Vacuum Dehyrating Systems |

5- Regeneration Units |

| 1-TRANSFORMER OIL FILTERS WITH WATER SEPARATOR | |||

|

|

||

|

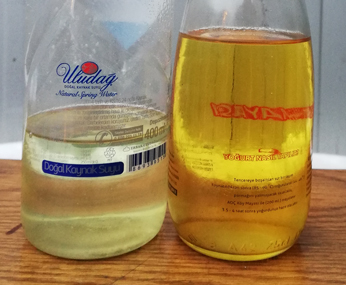

Above- right: Used transformer oil Above- left: Same oil after filtration. |

Above- right: Used transformer oil Above- left: Same oil after dehydrated. |

||

|

Transformer oil must be clean and free of water to perform its insulation property. Oil gets dirty before maintenance period is reached and dirty oil with humidity will accelerate oxidation. It is possible to use our filtration units to clean and dehdrate the oil while the transformer is in use. |

|||

| Transformer Oil Condition Maintenance Units | |||

|

|

|

|

|

|||

| Transformer oil gets dirt while in use, this will affect insulation properties of the oil. Use our filtration unit with water absorbent elements to clean and dehydrate the oil while the transformer is in use. As the oil will be warm, there is no need to warm up and further strain the oil. | |||

| 2-TRANSFORMER OIL REGENERATION |

|

|

|

|

|

|

Used tranformer oil on top and same oil on right after regeneration. |

Above- right: Used transformer oil Above- left: Same oil after regeneration. |

| TURBINE OIL FILTRATION (GAS TURBINES - WIND GENERATORS) | ||

|

Turbine oil to lubricate the bearings must be ultra-cean and free of water to prevent oxidation. Sludge, debris, oxidation by-products and varnish, rust, particle contaminants and wear-out deposits will accumulate in the lube oil system. Oil coolers will be covered by varnish will reduce cooling and further accelerate oxidation. |

||

|

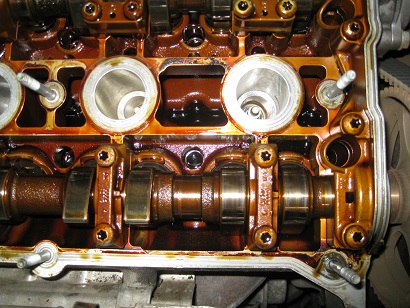

Turbine oil: dirty oil and the same oil filtered on the left. Dirt and aging-products in turbine oil will increase viscosity and further contribute to oxidation. High temperature is an oil killer, every 10 degrees over normal temperature will reduce oil life by half. The bearings and lube oil system will be affected. |

An oil cooler and bearing covered by sludge/varnish from oil-aging products |

|

|

|

|

| Filtration unit in process at a turbine station. On the left; heater arrangement and water absorbant elements are provided as optional. | Ex-proof turbine oil filtration units | Conventional filters supplied for turbine oil filtration | |

| WIND GENERATORS OIL FILTRATION AND DEHYDRATION | ||||||||||||||||

|

Wind turbine generators operate at high altitudesover 100 meters in an environment where the gearbox oil is subject to contamination and humidity under heavy wind and rain conditions. Maintence and repair is difficult and costly. Basic problems with wind geneator gearbox lube oil are:

|

|

||||||||||||||

Oil cleanliness

requirement for wind turbine gearbox oil

|

Emulsified oil and the same oil dehydrated. Water in free or emulsified state will cause damage to the components and cause oil degradation. |

|

||||||||||||||