|

WEAR GENERATES WEAR |

||

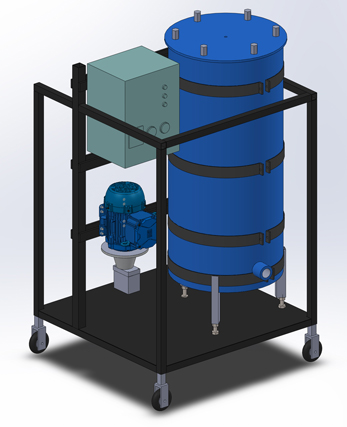

2- Filtration Units - Filtration Buggies

- Filtration buggies with traditional surface filter elements

4.1 - Units with Water Absorbants

4.2 - Vacuum Dehydraters

6- Strainers (cleanable-reusable filter elements)

7- Water Separators/Water Absorbant Units

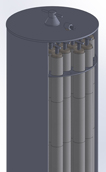

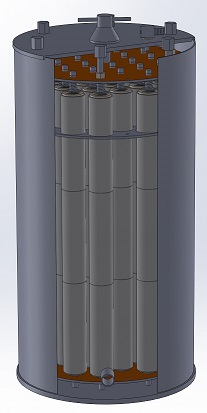

FILTERS WITH DEPTH FILTER ELEMENTS

Filters for oil and fuel

| ø90mm MF90X-X | PRODUCT | FUEL (L/Min) | HYDRAULIC OIL* (L/Min) | ENGINE OIL** | Sizes | ||||

|

2 m | 5m | 10m | 2 m | 5 m | 10 m | (2 m suggested) | mm | |

| MF901-X | 8 | 10 | 15 | 1,3 | 2 | 5 | 8-10 Liters Oil Pan | ø90mm L:346 mm | |

| MF902-X | 14 | 20 | 28 | 2,6 | 4 | 8 | 16-35 Liters Oil Pan | ø90mm L:525 mm | |

| MF904-X | 30 | 40 | 50 | 6 | 8 | 12 | 35-70 Liters Oil Pan | ø90mm L:875 mm | |

|

X signifies micron value of the elements |

Can be installed as on-board, in-line on fuel system. |

* For ISO VG46 oil @ 40 0C. Flow values will change depending on the viscosity and temperature. Pre-heating may be necessary in case of high viscosity and cold climates. **Suggested for on-board by-pass onnection. May be used as off-line filtration buggy. |

|||||||

| ø130mm MFX-X | PRODUCT | FUEL (L/Min) | HYDRAULIC* OIL (L/Min) | ENGINE OIL** | Sizes | ||||

|

1 m | 2 m | 5 m | 2 m | 5 m | 10 m | (2 m suggested) | mm | |

| MF1-X | 5 | 8 | 10 | 1 | 2 | 4 | 10-16 Liters Oil Pan | ø130mm L:346 mm | |

| MF2-X | 10 | 15 | 20 | 2 | 4 | 8 | 16-35 Liters Oil Pan | ø130mm L:525 mm | |

| MF4-X | 20 | 30 | 40 | 4 | 8 | 16 | 35-70 Liters Oil Pan | ø130mm L:875 mm | |

|

X signifies micron value of the elements |

Can be installed as on-board, in-line on fuel system. |

* For ISO VG46 oil @ 40 0C. Flow values will change depending on the viscosity and temperature. Pre-heating may be necessary in case of high viscosity and cold climates. **Suggested for on-board by-pass onnection. May be used as off-line filtration buggy. |

|||||||

| ø170mm 4MFX63-X | PRODUCT | FUEL (L/Min) | HYDRAULIC* OIL (L/Min) | ENGINE OIL** | Sizes | ||||

|

1 m | 2 m | 5 m | 1 m | 2 m | 5 m | (1-2 m suggested) | mm | |

| 4MF263-X | 30 | 40 | 80 | 6 | 8 | 20 | 70-120 Liters Oil Pan | ø170mm L:525 mm | |

| 4MF463-X | 60 | 80 | 150 | 12 | 16 | 40 | 120-200 Liters Oil Pan | ø170mm L:875 mm | |

|

X signifies micron value of the elements |

Can be installed as on-board, in-line on fuel system. |

* For ISO VG46 oil @ 40 0C. Flow values will change depending on the viscosity and temperature. Pre-heating may be necessary in case of high viscosity and cold climates. **Suggested for on-board by-pass onnection. May be used as off-line filtration buggy. |

|||||||

| ø220mm 7MFX63-X | PRODUCT | FUEL (L/Min) | HYDRAULIC* OIL (L/Min) | ENGINE OIL** | Sizes | ||||

|

1 m | 2 m | 5 m | 1 m | 2 m | 5 m | (1-2 m suggested) | mm | |

| 7MF263-X | 50 | 70 | 100 | 12 | 14 | 20 | 70-120 Liters Oil Pan | ø220mm L:525 mm | |

| 7MF463-X | 100 | 140 | 200 | 24 | 28 | 40 | 120-200 Liters Oil Pan | ø220mm L:875 mm | |

|

X signifies micron value of the elements |

Can be installed as on-board, in-line on fuel system. |

* For ISO VG46 oil @ 40 0C. Flow values will change depending on the viscosity and temperature. Pre-heating may be necessary in case of high viscosity and cold climates. **Suggested for on-board by-pass connection. May be used as off-line filtration buggy. |

|||||||

| ø350mm 19MF463-X | PRODUCT | FUEL (L/Min) | HYDRAULIC* OIL (L/Min) | ENGINE OIL** | Sizes | ||||

|

1 m | 2 m | 5 m | 1 m | 2 m | 5 m | (1-2 m suggested) | mm | |

| 19MF263-X | 120 | 190 | 250 | 32 | 38 | 60 | 200-800 Liters Oil Pan | ø350mm L:525 mm | |

| 19MF463-X | 240 | 280 | 500 | 64 | 76 | 120 | 800-1200 Liters Oil Pan | ø350mm L:875 mm | |

|

X signifies micron value of the elements |

Can be installed as on-board, in-line on fuel system. |

* For ISO VG46 oil @ 40 0C. Flow values will change depending on the viscosity and temperature. Pre-heating may be necessary in case of high viscosity and cold climates. **Suggested for on-board by-pass connection. May be used as off-line filtration buggy. |

|||||||

| ø350mm 19MF463-X | PRODUCT | FUEL (L/Min) | HYDRAULIC* OIL (L/Min) | ENGINE OIL** | Sizes | ||||

|

1 m | 2 m | 5 m | 1 m | 2 m | 5 m | (1-2 m suggested) | mm | |

| 30MF263-X | 220 | 300 | 450 | 50 | 60 | 90 | 1000-1600 Liters Oil Pan | ø350mm L:525 mm | |

| 30MF463-X | 450 | 600 | 900 | 100 | 120 | 180 | 1600-3000 Liters Oil Pan | ø350mm L:875 mm | |

|

X signifies micron value of the elements |

Can be installed as on-board, in-line on fuel system. |

* For ISO VG46 oil @ 40 0C. Flow values will change depending on the viscosity and temperature. Pre-heating may be necessary in case of high viscosity and cold climates. **Suggested for on-board by-pass connection. May be used as off-line filtration buggy. |

|||||||

FILTERS WITH TRADITIONAL SURFACE FILTER ELEMENTS

|

|

|

|

|

|

Traditional surface filters with high flow rate. Elements with high Beta ratio (1000) are obtained from Hydac and Bosch Rexroth). Filter bodies are our own design; to eliminate internal leakage, additional thrust sealing has been provided in addition to axial O-ring. Consult us for capacity required for your application. |

||||

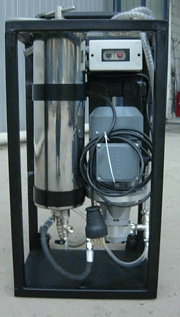

| PU-MF1/PU-MF2 | PU-1MF4-X | PU-4MF2-X | PU-4MF4-X | PU-7MF4-63-X |

|

|

|

|

|

|

Configuration -220/380 VAC elec. motor -Thermil protective switch -5 bar pressure relief valve -Pressure Gauge

Filters Used: For Oil: MF1: 1 L/Min MF2: 2 L/Min MF901: 1,2 L/Min MF902: 2,4 L/Min For Fuel: MF1: 5 L/Min MF2: 10 L/Min MF901: 8 L/Min MF902: 12 L/Min |

Configuration -220/380 VAC electric motor -Thermal protective switch -5 bar pressure relief valve -Pressure Gauge

Filters Used: For Oil: 4 L/dak (for 40 0C ISOVG46 oil). For Fuel: 20 L/Min |

Configuration -220/380 VAC electric motor -Thermal protective switch -5 bar pressure relief valve -Pressure Gauge

Filters Used: For Oil: 2MF4: 8 L/Min For Fuel: 2MF4: 40 L/Min

|

Configuration -220/380 VAC electric motor -Thermical switch -5 bar pressure relief valve -Pressure Gauge

Filters Used: For Oil: 4MF4: 8 L/Min For Fuel: 4MF4: 40 L/Min

|

Configuration -220/380 VAC electric motor -Thermical switch -5 bar pressure relief valve -Pressure Gauge Optional water absorbant element and preheating. Filters Used: For Oil: MF904: 20L/min (2 m filter and 40 0C ISOVG46 oil. For Fuel: MF904: 120 L/dMin (Fuel) |

| PU-19MF263 | PU-19MF463 | PU-30MF263 | PU-30MF463 | HIGHER CAPACITIES |

|

|

|

||

|

||||

|

Dia: 345 mmx L525 mm 19 filter elements For Oil: 38 L/min For Fuel:190 L/min |

Dia: 345 mmxL:950 mm 19 filter elements For Oil: 76 L/min For Fuel:380 L/min |

Dia: ¢490 mmxL:525 mm 30 filter elements For Oil: 60 L/min For Fuel:300 L/min |

Dia: 490 mmxL:950 mm 30 filter elements For Oil: 120 L/min For Fuel:600 L/min |

Filtration units up to 900 L/Min (54 ton/h) have been delivered to customers. Call us for further information |

|

|

|

||||||||||

|

|

| PU-1MF1.63-02 |

FILTRATION UNIT FOR ENGINE OIL AND FUEL FOR PASSENGER CARS AND LIGHT COMMERCIAL VEHICLES |

|

1,2 L/Min Pump, 120 W; 1500 D/D; 220VAC motor Max Pressure 3 bars |

MAINTENANCE FILTRATION UNIT For Engine Oil and Fuel Used for periodical maintenance of engine lube oil. CAn be used as kidney unit to withraw oil from oil pan, circulate through filter and return the filter outlet back to the oil pan. 15-20 min of filtration will be enough to have the oil cleaned thoroughly. Advantages: - Extends oil life (Analysis prove that contamination and soot level make it necessary to replace oil before the physical and chemical life of the oil is depleted). - Extends the life of OEM oil filter elements. - Prevents bearing wear and extends engine overhaul life. |

|

|

FUEL FILTRATION You can clean the fuel tank of your vehicle. Use filter elements with water absorbant outer layer if existance of water is a big problem. Advantages:Clean fuel means? - 3-7 % of fuel saving (contaminant and water free fuel will provide optimal combustion in the cylinder). - Extends OEM fuel filter life by 3-4 times (ultra clean fuel free of water will take the dirt load of the OEM filters) - Protects fuel injectors and fuel pumps from blockage, wear and erratic operation (Common Rail fue injection systems work under very high pressures. Dirt particles in fuel results in wear on injector nozzles and fuel pressure pump). - Diesel particle filters effective life will be increased due to much lower emmission levels. |

|

Can be configured with or without pump/motor powered. (PU: with motor/pump; KU: without motor/pump)

Ask for higher capacities |

|||||||||||||||||||||||||||||||||||||||||

TRANSFORMER OIL FILTRATION UNITS

UNITS WITH WATER ABSORBANT ELEMENTS

|

Units |

Prefilter + 1 m filter + Heater + Water Absorbant | ||

|

Capacity |

L/Min |

L/Hour | Water Holding Capacity |

|

PU/TOF-SA-1MF4-X |

16 |

1000 |

2-4-6 liters |

|

PU/TOF-SA-2MF4-X |

32 |

1800 | 4-6-8 liters |

|

PU/TOF-SA-4MF4-X |

60 |

3600 | 4-6-8-10 lliters |

|

PU/TOF-SA-7MF4.63-X |

100 |

6000 | 6-8-10-12 liters |

| PU/TOF-SA-19MF4.63-X | 300 | 18000 | 6-8-10-12-18 liters |

PROCESS: Oil is preheated to 50-60 0C and circulated through water absorbant elements and fine filter elements. Prefilter may be needed for excessively dirty oils. Oil oil can be recirculated until desired dryness and cleanliness is achieved. The oil after filtration is 2-3 levels cleaner than new oil.

|

|

|

|

| Dirty transformer oil samples (right side at each picture); and oil after dried and filtered | A small size unit | A larger size unit | |

|

A dirty transformer oil on the left; filtered once and twice on the right |

| Left:A 60 lpm unit |

|

|

|

| ZY Single Stage Vacuum Dehidrator | ZYD Double Stage Vacuum Dehidrator Unit |

| Vacuum Transformer Oil Purifier | ZY - Single Stage | ZYD - Double Stage | ||||

|

Tipi |

Unit | ZY30 | ZY50 | ZYD30 | ZYD50 | |

|

Flow |

L/H | 1800 | 1800 | 3000 | 3000 | |

|

Operating Vacuum |

MPa | -0.06~-0.095 | -0.08~-0.095 | |||

|

İOperating Pressure |

MPa | ≤ 0.4 | ≤ 0.4 | |||

|

Temperature Range |

0C | 20 ~ 80 | 20 ~ 80 | |||

|

Dielectric Resistence |

KV | ≥ 65 | ≥ 75 | |||

|

Water Content |

ppm | ≤ 5 | ≤ 3 | |||

|

Gas Content |

% | ≤ 0.1 | ≤ 0.1 | |||

|

Particle Size |

μ | ≤ 1 | ≤ 1 | |||

|

Flash Point (close cup) |

°C | ≥ 135 | ≥ 135 | |||

|

Hardness |

PH | ≥ 5.4 | ||||

|

Acid Number |

mgKOH/g | ≤ 0.03 | ||||

|

Dielectric- Factor Loss |

tgδ (90℃)% ≤ 0.005 | |||||

|

Power Feed |

380v 50Hz,3Ph (As per user’s option | |||||

|

Noise Level |

dB(A) | ≤ 65~85 | ||||

|

Heating Power |

Kw | 15 | 30 | 24 | 30 | |

|

Total gPower |

Kw | 16,5 | 33,5 | 27,7 | 35,5 | |

|

In-Out Port Sizes |

mm | f25 | f32 | f25 | f32 | |

|

Weight |

kg | 270 | 300 | 650 | 750 | |

|

Dimensions

|

L |

mm | 1050 | 1200 | 1500 | 1500 |

|

W |

mm | 750 | 950 | 1250 | 1250 | |

|

H |

mm | 1450 | 1500 | 1700 | 1750 | |

|

|

|

|

40 L/min capacity Cooking Oil Filter Filtration capability at 180 °C 400-200-50 micron pre-filters (strainers) (at pump inlet) 2 micron fine filter |

10 L/min capacity Cooking Oil Filter Filtration capability at 180 °C 150-100- (at pump inlet) and 50-25-10 micron pre-filters (strainers) before fine filters 2 micron fine filter Broşürü indir |

Micron rate of strainers: (µ: 5 -10 - 25 - 50 - 100 - 150).

|

Capacity |

Litre |

20 |

10 |

5 |

3 |

1 |

0,2 |

|

Diameter |

mm |

219 |

169 |

129 |

129 |

129 |

78 |

|

Length |

mm |

550 |

450 |

400 |

250 |

80 |

50 |

|

Strainer element micron values can be selected as 5-10-25-50-100-150 micron, possibility of use in serial mode. Strainer elements can be made cylindrical or flat surface type. Strainer body material can be stainless steel or carbon steel. |

|||||||

|

|

|

|

|

|

| Toplam ziyaret: |