|

WEAR GENERATES WEAR |

||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

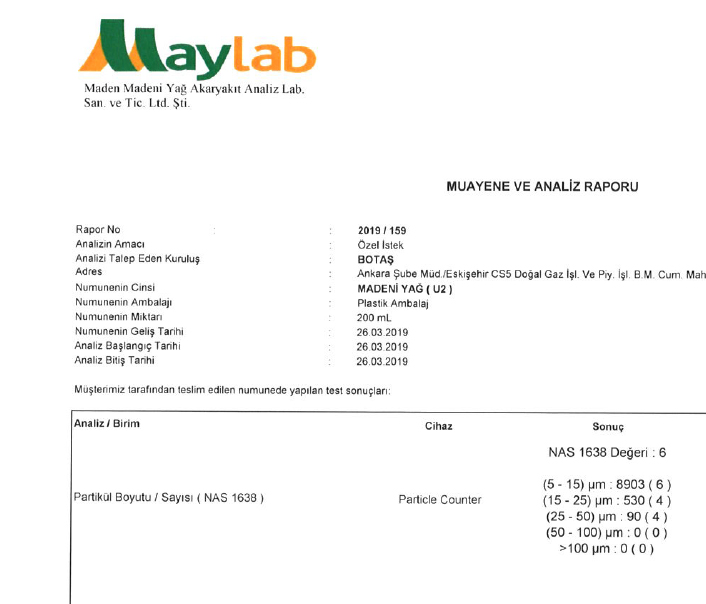

Filtration of

turbine oil at NAS12 in a natural gas station turbine oil;

contamination was reduced to NAS6 level which saved the

company from disposal of 5000 liters of oil. Contamination

level was reduced by %98,5. |

Filtration unit to

filter plastic injection machine oil.

|

Unit capacity is 8 L/Min, it has 2 lters water separator. On right, dirty oil, on left bottle, filtered oil    12 liter/min 1

micron filtration unit with heater and water absorbant filter.

|

As the unit is used to filter high viscosity gear oil, oil heater is to be used to pass the oil through the tightly wound filter elements.    |

||||||||||||||||||||||

| Filter

to clean extrusion machine oil:

20 litre/min (1440 liters/hour) filtration unit has 4 liter water separator before the main filters. It is possible to change direction of oil by controlling 3-way valves. Water separator can be used independently to only dehydrate the oil. |

|

|

|

| Filtration unit

to filter engine oil:

The unit is 4 liter/min capacity, with 1 kW heater, water separator, electronic control panel. The filter is 2 micron and protected by 5 bar pressure relief valve. Water separator is 1 litre.

|

|

|

|

|

Cooking oil filtration machine:

The unit is capable to filter hot cooking oil at 1800C. It has 50-25-10-02 micron prefilters before the fine filter and 150 micron suction strainer before the pump inlet. Pump, filters, strainer and flexible hosess are SS304 stainles steel; the sealings are teflon. It is possible to remove ste strainers without need to remove fine filters. |

|

|

|

|

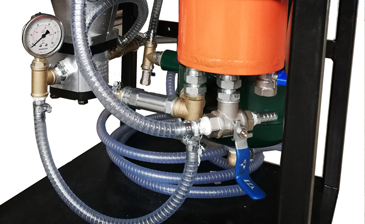

14 L/Min filtration unit to clean hydraulic oil. The unit also has

water separator in the flter body.

|

|

|

|

|

Filtration unit to clean CAT engine oil after dynamo test of the

engine. COntamination after test is reduced to engine

manufacturer's requirement thereby saving 200 liters of engine oil

which is used on large mining trucks.

Unit capacity is 40 L/min and equipped with CAT prefilter and final 2 micron depth filter elements. Unit has 10 kW heater for cold weather operations. |

|

|

?ce filtre ?cesi CAT filtre. |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Toplam ziyaret: |