|

WEAR GENERATES WEAR |

||

Clean your oil with our ultra-fine filtration systems, extend the oil life, protect your machine

|

ENGINE OIL FILTRATION SYSTEMS |

|

Use our fine micron depth filter to collect soot |

|

Engine beraing safety is more important than engine oil life as main and journal bearings are separated from crank shaft by a thin lubricator film. Particles (dust and wear metal) in this lube oil film will make oil abrasive and reduce bearing life, thus engine performance. Wear will accelerate wear.

APPLICATION ALTERNATIVES

1- In-line by-pass

on lube oil system

2- Mobile filtration unit for maintenance

purposes |

|

|

Bearing of a truck, with by-pass filter aplied on-board, after 1,000,000 km |

Top left, used engine oil; top right same oil after filtation |

|

IN-LINE BY-PASS CONNECTION |

A by-pass filter is connected to lube oil circuit. Engine oil cleanliness is assured at ideal cleanliness level and OEM filter's service life is extended 3-4 times. | ||

|

ENGINE OIL becomes black as it is used, the color doesn't indicate the oil is unusable. It is the TBN value and viscosity that determines if the oil is good. Particle contamination and soot are other factors to judge the state of the oil. But these are external factors that can be filtered to make oil good again. Basic factors to drain oil are: - When TBN (Total Base Number)value drops to 50% of what it was originally. - When viscosity changes by 10%. |

|

|

|

| BUT soot and particle contamination are important since they accelerate bearing wear, make oil thick and negatively affect cooling of oil. | |||

|

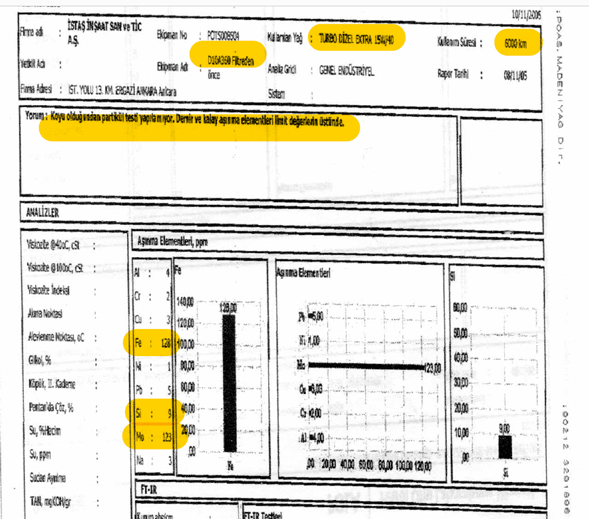

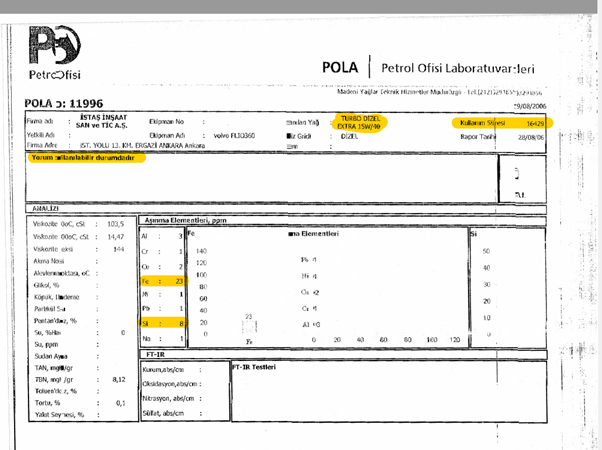

CONCRETE MIXER TRUCK ENGINE: Field surveys and lab analysis show that engine oil is to be drained due to soot concentration before the oil's qualities are degraded. Soot mixed with silica and wear metals will act like an abrasive. The report below, for a truck concrete mixer, shows that the oil becomes too dirty even though TBN and viscosity are within limits. The oil was on 6000 km and oil drain interval was 8000 km (already reduced from 15000 km). A by-pass filter was fit and oil report was OK when the same oil was on 16,000 km. Truck ran 20,000 km before it was submitted for maintenance. |

YOUR ADVANTAGES

- Extended oil life - Extended OEM filter element life by 3-4 times - Reduced engine bearings wear - Improved engine performance |

| Ara?zeri Uygulama Sonu?arížŊb> | |

|

|

|

Oil analysis of a concrete truck mixer's engine oil on 6000 km. before the by-pass filter was fit. Fe 128, Molibdenium 123, Na- 3; TBN 7,05 (For larger image Click) |

Ayn?a?iltre tak?d?tan sonra 16000 km ?l?mada ya?nalizi ya?n kullan?abilir durumda oldu?nu g?teriyor; TBN 8,15 ile bir derece iyile?e g?teriyor, Demir 23 ppm, Bu yaÍ 22000 km'ye akadar kullan?abilir durumda ?l?m?t?. Motor revizyon d?emi geldi?nden izleme sonland??m?t? (Resmi b?? g?mek i?n t?lay?) |

|

For applicable filters: http://www.mikronfiltre.com/urun.html |

|

|

|

|

BAKIM AMA?I OFF-LINE TEM?LEME |

|||

|

Motor ya?ar?? harici bir filtrasyon cihaz?le karter i?risine veya karterden d?ar?l?arak temizlenmesi ama???. Ayn?ip ya?ullan?an ara?a?ar?? bir yerde topan?opluca temizlenmesi de s? konusu olabilir (motor onar?-revizyon, veya motor ya?ar?? biriktirilip ba?a uygulamalar i?n kullan?í gibi durumlar). Farkl?ip ya?ar? kar?t??mamasí gerekir. Ayn?nite ile hem motor hem hidrolik yaÍ temizli? yap?masíŽ ya?ar? birbirlerini bozabilece? nedeniyle, uygun de?ldir. |

|||

|

|

||

|

Motor ya?, bo?ltmaks??, karteden ?kilerek filtra edildikten sonra tekrar kartere verilebilir. |

CAT Kaya Kamyonu motorlar?? ya?n?estten sonra temizlemek i?n kullan?an 40 L/Dak filtrasyon cihazížŊfont> |

Binek arac?otor ya? dibinde zamanla ?ken tortu,; filtrelenmi?a?a ayn??ede tortu ?kmesi g??m?or. |

|

|

Uygulanabilir filtrasyon ?iteleri i?n http://www.mikronfiltre.com/urun.html |